Contact: +52 332152-0977

Contact: +52 332152-0978

info@deprag.mx

DEPRAG México

DEPRAG Amberg

Service

The suitable feeding technology for the material you need to feed

Different parts and connection-elements often require also different feeding technologies.

Here, you can find a small sample of different components with the selection of an appropriate DEPRAG feeder:

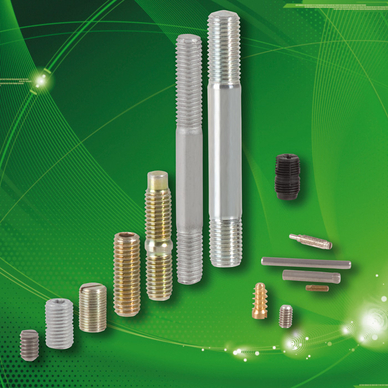

Screws

For the processing of screws, we offer a size-adapted vibratory feeder or a sword (segment) feeder. When starting to automate your assembly process, we recommend our screw presenter.

Here, we can offer standard systems both for handheld as well as stationary applications.

Please use our comprehensive guideline to select the suitable feeding device.

Pins

For the processing of pins, we recommend a vibratory feeder.

And, for standardized applications, we can offer handheld feed systems. Stationary applications are often carried out by using an adapted separator.

Nuts

For the processing of nuts, we recommend a vibratory feeder.

And, for standardized applications, we can offer handheld as well as stationary standard feed-systems.

O-Rings

For the processing of O-rings, we recommend a vibratory feeder.

Our feed-systems can be implemented as part of an assembly solution into stationary machines. The O-ring will be presented into a pickup-position, stretched by an assembly-module and positioned.

Please find an application example here.

Components

We are able to process many different components with our vibratory feeder in combination with a linear-conveyor that sorts and presents the component.

Using an array of sensors allows us to process varying component-geometries in our stationary feed systems.

Parts to be press-fitted

For the processing of rivets, pins, sleeves and balls, we can offer our standardized press-insertion systems consisting of a pressurization device connected to either a vibratory feeder or a sword (segment) feeder.