Contact: +52 332152-0977

Contact: +52 332152-0978

info@deprag.mx

DEPRAG México

DEPRAG Amberg

Service

Sequence controller and process monitoring

- process-reliable

- flexible

- functional variety

- easy to maintain

- easy to operate

Screwdriving Controller

Besides the screwdriver, the screwdriving controller is an essential component of the electronic screwdriving system. According to the parameterized screw-tightening process, the controller controls the EC-drive of the screwdriver, evaluated the measuring signals and provides all necessary operator- and documentation functions.

The offered EC- and EC-Servo systems are both equipped with highly dynamic brushless servo-motors; they differ in the way the torque measurements are generated.

While the EC-technology used with the sequence controllers AST5 and AST11 are based on the exact motor-current measurement, the EC-Servo system with the controller AST30-31 and AST40 evaluates the signals of the transducer integrated in the tool.

Additional selection criteria’s for the application-specific and best-suitable screwdriving system – besides the torque values – are the different possibilities for the documentation of the screwdriving-result, as well as the diverse interface to integrate with the system environment.

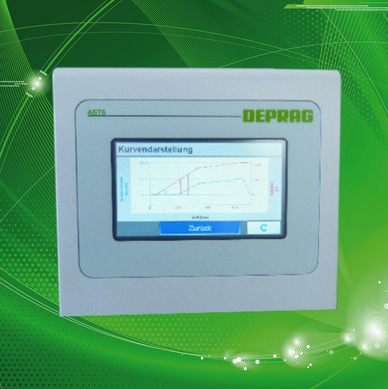

AST5

- torque range: 0.01 Nm – 2 Nm

- screwdriver design: inline, handheld Screwdriver with trigger-start or push-to-start, screwdrivers designed for automatic screwfeeding

- number of possible multistage programs: 100

- documentation possibility: internal storage, retrieval via Ethernet (Datalogger, touchscreen)

- operator friendly color touch-screen for the direct input of screwdriving cycles and tightening parameter, graphical display of torque-curves

- small size for confined spaces at manual workstations

AST6

- torque range: 0.02 Nm – 0.8 Nm

- for NANOMAT-EC and MICROMAT-EC screwdriver spindles

- number of possible multistage programs: 100

- documentation possibility: internal storage, retrieval via Ethernet (Datalogger, touchscreen)

- operator friendly color touch-screen for the direct input of screwdriving cycles and tightening parameter, graphical display of torque-curves

- small size for confined spaces

AST11

- torque range: 0.03 Nm – 25 Nm

- screwdriver design: stationary screwdrivers inline, handheld screwdriver inline, angle-head screwdrivers, pistol-grip screwdrivers, screwdrivers designed for automatic screwfeeding

- number of possible multistage programs: 16

- documentation possibility: internal storage, retrieval via Ethernet (Datalogger, http), parameterizable printer port

- PLC-ports: I/O, Profibus

AST30-31

- torque range: 7 Nm – 120 Nm

- screwdriver design: handheld screwdriver in angle-head form

- number of possible multistage programs: 32

- documentation possibility: internal storage, output via RS232 or Ethernet (Datalogger), printer port

- PLC-ports: I/O, Profibus

AST40

- torque range: 0.2 Nm – 500 Nm

- screwdriver design: stationary screwdrivers inline and with angle-head drive, also for handheld screwdriver applications in connection with add-on components

- number of possible multistage programs: 100

- documentation possibility: internal storage, output via RS232 or Ethernet (Datalogger), printer port

- PLC-ports: I/O, Profibus

Function Controllers – fc

Function controllers are used to the increase of the process reliability in the manual screw-assembly. They allow the supervision of each individual tightening-process and guarantee the completeness of the screw-connection on a given product.

Screwdriver Function Control fc11

Screwdriver function control fc11 and the handheld xcrewdrivers of the MICROMAT-F/MINIMAT-F series offer an intelligent, process reliable solution.

This screwdriving system counts the assembled screws, monitors their screwdriving time, shuts off only when the preset torque is reached and recognizes a part-change – it controls itself 100 % and eliminates an expensive inspection.

Screwdriver Function Control fc20

The fc20 can also monitor complex assembly processes using programmable sequences. The controller can also manage up to 3 different screwdriver model connections for complex multi layer assemblies, which may require different screws and torques.