Contact: +52 332152-0977

Contact: +52 332152-0978

info@deprag.mx

DEPRAG México

DEPRAG Amberg

Service

Design and functionality of a turbine motor

Design and functionality of a turbine motor

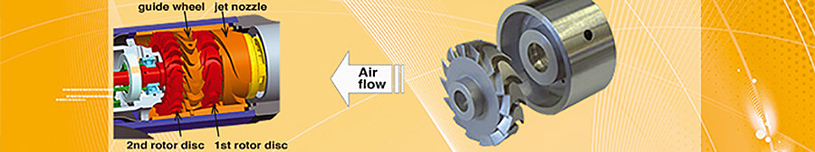

Pneumatic turbines are continuous-flow machines, which can be executed in single-stage or dual-stage design.

The conversion of the pressure energy into kinetic energy takes place in the inlet nozzle. On a two-stage turbine, the largest part of the kinetic energy is converted in the 1st turbine wheel. The air-flow is diverted over the stationary turbine wheel. The remaining energy is converted in the 2nd turbine wheel.

The turbine does not require any contact seals. Therefore, the operation of the turbine with non-lubricated compressed-air is totally free from wear. Continuous-flow machines optimally utilize the energy of the compressed air. Therefore, the air requirement of a turbine motor is 1/3rd less when compared to an pneumatic vanemotor. The power to weight ratio [kg/kW] is only half.

Additional information:

Technical Information:PDF Product Catalog D 6000