Contact: +52 332152-0977

Contact: +52 332152-0978

info@deprag.mx

DEPRAG México

DEPRAG Amberg

Service

Infinite variable regulation of the air pressure or air volume

Infinite variable regulation of the air pressure or air volume

Your airmotor is very flexible:

The speed can be adjusted to fit your requirements.

Speed change can be achieved by varying the air pressure, changing the air volume or more commonly by a combined regulation of air pressure and air volume.

Speed change through load change:

The speed of the airmotor automatically adapts to the load changes.

This means that unloaded, the airmotor operates at idle speed.

If there is increased load (low torque) the nominal speed is close to the idle speed.

With increased load (increased torque), the speed decreases.

Energy Efficiency:

An pneumatic motor achieves its maximum power when it is operating as close as possible to its rated speed (50% of the rated idle speed). The energy balance is best in this area because the compressed air is used efficiently.

Theoretical power curves are available for all DEPRAG pneumatic motors. Please ask us for additional information.

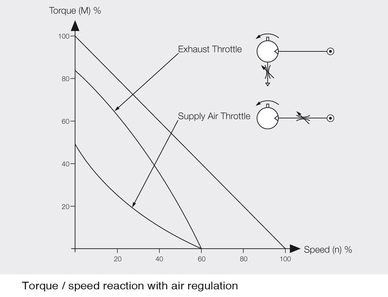

Regulating the speed by air volume:

Through throttling the exhaust air, a speed reduction of the pneumatic motor is achieved without any considerable loss of performance or torque. If you would like to reduce the power output or the torque in addition to the speed, then an air inflow throttle is recommended.

Regulating the speed by air pressure:

The operating data of the DEPRAG airmotor is based on an operating air pressure of 6 bar. By adjusting the pressure in the range of 4 to 6.3 bars you can manipulate the speed, power, torque and air consumption of your pneumatic motor without problems. The following correctional factors are applicable to achieve the desired adaptation:

Do you require support for the regulation of your compressed airmotor?

Our application consultants are here to support you at anytime.